-

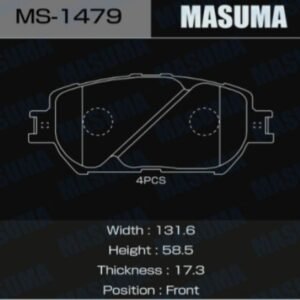

Front Brake Pads For LEXUS ES300, ES330, GS300, IS250, IS250/300, IS250C, TOYOTA Camry, Crown, Crown Athlete, Crown Majesta, Crown Royal Saloon, Isis, Mark X, Solara coupe (USA), Windom, Wish, Yaris/Vios/Limo – (PN1479/MS1479)

Ceramic brake pads are composed of a mix of ceramic fibers, non-ferrous filler materials, and a binding resin. They are engineered to withstand high temperatures generated during braking and provide reliable stopping power.

Advantages:

- Performance: Ceramic brake pads offer excellent stopping power, providing consistent and smooth braking performance across a wide range of temperatures.

- Durability: They are known for their longevity, as ceramic compounds tend to wear down brake rotors less compared to other materials like semi-metallic pads. This leads to reduced rotor wear and potentially longer brake pad lifespan.

- Low Noise: Ceramic brake pads typically produce less noise during braking compared to metallic counterparts. This can enhance driving comfort and reduce brake squeal.

- Less Dust: Ceramic pads generate less brake dust compared to semi-metallic pads. This can help in maintaining cleaner wheels and reduce the need for frequent cleaning.

- Resistance to Fade: They have good thermal stability, meaning they are less prone to brake fade, a phenomenon where braking efficiency decreases due to overheating during prolonged or aggressive braking.

Purpose of Use:

Ceramic brake pads are widely used in various automotive applications, from daily commuting vehicles to high-performance sports cars. They are particularly favored in situations where low noise, minimal dust, and consistent braking performance are desired. Additionally, their resistance to fade makes them suitable for heavy-duty or high-temperature braking situations, such as towing or driving in mountainous terrain. Overall, ceramic brake pads offer a balanced combination of performance, durability, and comfort for a wide range of driving conditions.SpecificationsTypeBRAKE PADSLocationFront Axle BrakeLength-1131.6Pcs In Set4Thickness-117.3Width-158.5$57.88 -

Front Brake Pads For LEXUS GS200T, GS250, GS300, GS300H, GS350, GS430, GS450H, GS460, IS200t, IS250/300, IS300, IS300C, IS300H, IS350,IS350C, RC200t, RC300, RC300h, RC350, TOYOTA Crown, Crown (CHINA), Crown Athlete, Crown Majesta, Mark X – (PN1547/MS-1547)

Ceramic brake pads are composed of a mix of ceramic fibers, non-ferrous filler materials, and a binding resin. They are engineered to withstand high temperatures generated during braking and provide reliable stopping power.

Advantages:

- Performance: Ceramic brake pads offer excellent stopping power, providing consistent and smooth braking performance across a wide range of temperatures.

- Durability: They are known for their longevity, as ceramic compounds tend to wear down brake rotors less compared to other materials like semi-metallic pads. This leads to reduced rotor wear and potentially longer brake pad lifespan.

- Low Noise: Ceramic brake pads typically produce less noise during braking compared to metallic counterparts. This can enhance driving comfort and reduce brake squeal.

- Less Dust: Ceramic pads generate less brake dust compared to semi-metallic pads. This can help in maintaining cleaner wheels and reduce the need for frequent cleaning.

- Resistance to Fade: They have good thermal stability, meaning they are less prone to brake fade, a phenomenon where braking efficiency decreases due to overheating during prolonged or aggressive braking.

Purpose of Use:

Ceramic brake pads are widely used in various automotive applications, from daily commuting vehicles to high-performance sports cars. They are particularly favored in situations where low noise, minimal dust, and consistent braking performance are desired. Additionally, their resistance to fade makes them suitable for heavy-duty or high-temperature braking situations, such as towing or driving in mountainous terrain. Overall, ceramic brake pads offer a balanced combination of performance, durability, and comfort for a wide range of driving conditions.SpecificationsTypeBRAKE PADSLocationFront Axle BrakeLength-1118.6Pcs In Set4Thickness-117.3Width-177.5$61.80 -

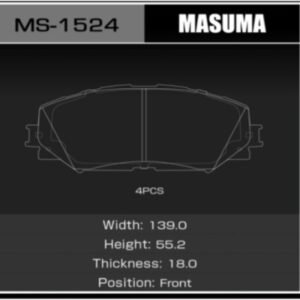

Front Brake Pads For LEXUS HS250h, TOYOTA Allion, Auris,Blade, Comfort, Corolla, Corolla Altis, Corolla Axio, Corolla Fielder, Corolla Rumion, Ist, JPN TAXI, Matrix, NAV1, Noah/Voxy, Prius Alpha, RAV 4, Rumion, Sai, Scion XB, Scion XD, Sienta, Townace, Urban Cruiser, Verso-S, Wish, PONTIAC (GM) VIBE II, MITSUOKA NOUERA 6-02, DAIHATSU Mebius – (PN1524/MS-1524)

Ceramic brake pads are composed of a mix of ceramic fibers, non-ferrous filler materials, and a binding resin. They are engineered to withstand high temperatures generated during braking and provide reliable stopping power.

Advantages:

- Performance: Ceramic brake pads offer excellent stopping power, providing consistent and smooth braking performance across a wide range of temperatures.

- Durability: They are known for their longevity, as ceramic compounds tend to wear down brake rotors less compared to other materials like semi-metallic pads. This leads to reduced rotor wear and potentially longer brake pad lifespan.

- Low Noise: Ceramic brake pads typically produce less noise during braking compared to metallic counterparts. This can enhance driving comfort and reduce brake squeal.

- Less Dust: Ceramic pads generate less brake dust compared to semi-metallic pads. This can help in maintaining cleaner wheels and reduce the need for frequent cleaning.

- Resistance to Fade: They have good thermal stability, meaning they are less prone to brake fade, a phenomenon where braking efficiency decreases due to overheating during prolonged or aggressive braking.

Purpose of Use:

Ceramic brake pads are widely used in various automotive applications, from daily commuting vehicles to high-performance sports cars. They are particularly favored in situations where low noise, minimal dust, and consistent braking performance are desired. Additionally, their resistance to fade makes them suitable for heavy-duty or high-temperature braking situations, such as towing or driving in mountainous terrain. Overall, ceramic brake pads offer a balanced combination of performance, durability, and comfort for a wide range of driving conditions.SpecificationsTypeBRAKE PADSLocationFront Axle BrakePositionLeft/RightLength-1139.2Pcs In Set4Thickness-117.3Width-155.5$52.60 -

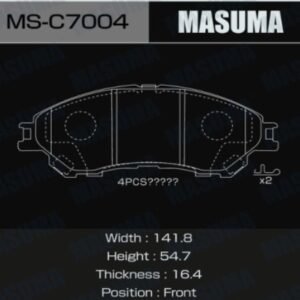

Front Brake Pads For SUZUKI Escudo, SX4 S-Cross, Vitara, NISSAN Livina, MITSUBISHI Xpander- (PN9809/MS-C7004)

Ceramic brake pads are composed of a mix of ceramic fibers, non-ferrous filler materials, and a binding resin. They are engineered to withstand high temperatures generated during braking and provide reliable stopping power.

Advantages:

- Performance: Ceramic brake pads offer excellent stopping power, providing consistent and smooth braking performance across a wide range of temperatures.

- Durability: They are known for their longevity, as ceramic compounds tend to wear down brake rotors less compared to other materials like semi-metallic pads. This leads to reduced rotor wear and potentially longer brake pad lifespan.

- Low Noise: Ceramic brake pads typically produce less noise during braking compared to metallic counterparts. This can enhance driving comfort and reduce brake squeal.

- Less Dust: Ceramic pads generate less brake dust compared to semi-metallic pads. This can help in maintaining cleaner wheels and reduce the need for frequent cleaning.

- Resistance to Fade: They have good thermal stability, meaning they are less prone to brake fade, a phenomenon where braking efficiency decreases due to overheating during prolonged or aggressive braking.

Purpose of Use:

Ceramic brake pads are widely used in various automotive applications, from daily commuting vehicles to high-performance sports cars. They are particularly favored in situations where low noise, minimal dust, and consistent braking performance are desired. Additionally, their resistance to fade makes them suitable for heavy-duty or high-temperature braking situations, such as towing or driving in mountainous terrain. Overall, ceramic brake pads offer a balanced combination of performance, durability, and comfort for a wide range of driving conditions.SpecificationsTypeBRAKE PADSLocationFront Axle BrakeBrake SystemAkebonoLength-1141.8Pcs In Set4Thickness-116Width-155$58.88 -

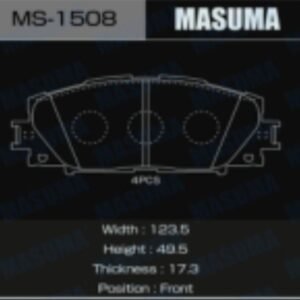

Front Brake Pads For TOYOTA Belta, Allion, Corolla Axio, Passo, Porte/Spade, Probox, Spade, Vios, Vitz, Yaris, Yaris (USA), LIFAN Lifan X50, PERODUA Alza – (PN1508/MS-1508)

Ceramic brake pads are composed of a mix of ceramic fibers, non-ferrous filler materials, and a binding resin. They are engineered to withstand high temperatures generated during braking and provide reliable stopping power.

Advantages:

- Performance: Ceramic brake pads offer excellent stopping power, providing consistent and smooth braking performance across a wide range of temperatures.

- Durability: They are known for their longevity, as ceramic compounds tend to wear down brake rotors less compared to other materials like semi-metallic pads. This leads to reduced rotor wear and potentially longer brake pad lifespan.

- Low Noise: Ceramic brake pads typically produce less noise during braking compared to metallic counterparts. This can enhance driving comfort and reduce brake squeal.

- Less Dust: Ceramic pads generate less brake dust compared to semi-metallic pads. This can help in maintaining cleaner wheels and reduce the need for frequent cleaning.

- Resistance to Fade: They have good thermal stability, meaning they are less prone to brake fade, a phenomenon where braking efficiency decreases due to overheating during prolonged or aggressive braking.

Purpose of Use:

Ceramic brake pads are widely used in various automotive applications, from daily commuting vehicles to high-performance sports cars. They are particularly favored in situations where low noise, minimal dust, and consistent braking performance are desired. Additionally, their resistance to fade makes them suitable for heavy-duty or high-temperature braking situations, such as towing or driving in mountainous terrain. Overall, ceramic brake pads offer a balanced combination of performance, durability, and comfort for a wide range of driving conditions.SpecificationsTypeBRAKE PADSLocationFront Axle BrakePositionLeft/RightLength-1122.7Pcs In Set4Thickness-117Width-149$54.90 -

Front Ceramic Brake Pad for MAZDA CX-5, JEEP Cherokee, DODGE Dart, CHRYSLER 200 – (PN25000/ MS-5908)

Ceramic brake pads are composed of a mix of ceramic fibers, non-ferrous filler materials, and a binding resin. They are engineered to withstand high temperatures generated during braking and provide reliable stopping power.

Advantages:

- Performance: Ceramic brake pads offer excellent stopping power, providing consistent and smooth braking performance across a wide range of temperatures.

- Durability: They are known for their longevity, as ceramic compounds tend to wear down brake rotors less compared to other materials like semi-metallic pads. This leads to reduced rotor wear and potentially longer brake pad lifespan.

- Low Noise: Ceramic brake pads typically produce less noise during braking compared to metallic counterparts. This can enhance driving comfort and reduce brake squeal.

- Less Dust: Ceramic pads generate less brake dust compared to semi-metallic pads. This can help in maintaining cleaner wheels and reduce the need for frequent cleaning.

- Resistance to Fade: They have good thermal stability, meaning they are less prone to brake fade, a phenomenon where braking efficiency decreases due to overheating during prolonged or aggressive braking.

Purpose of Use:

Ceramic brake pads are widely used in various automotive applications, from daily commuting vehicles to high-performance sports cars. They are particularly favored in situations where low noise, minimal dust, and consistent braking performance are desired. Additionally, their resistance to fade makes them suitable for heavy-duty or high-temperature braking situations, such as towing or driving in mountainous terrain. Overall, ceramic brake pads offer a balanced combination of performance, durability, and comfort for a wide range of driving conditions.$59.10 -

front door wreath

- DESIGN: Our welcome sign have a history of twelve years, with skilled craftsmanship, durable products, and a variety of colors and texts to choose from.

$29.99front door wreath

$29.99 -

Front Engine Mount for SUZUKI Escudo, Grand Vitara, Vitara, MAZDA Proceed Levante – SZM-004, 11610-65D00 – (B00R97KTVM)

Engine mounts are components that secure the engine to the vehicle’s chassis and absorb vibrations and shocks generated by the engine during operation. They play a crucial role in supporting the engine’s weight, reducing noise and vibrations, and isolating the engine’s movements from the rest of the vehicle.

The placement of engine mounts varies depending on the vehicle’s design, but they are typically located between the engine and the vehicle’s frame or subframe. Engine mounts are designed to withstand the engine’s weight and the forces generated during acceleration, braking, and cornering.

When it comes to compatibility, it is essential to ensure that the engine mounts are compatible with the specific make and model of the vehicle. Using compatible engine mounts designed for your vehicle ensures proper fitment and functionality, reducing the risk of premature wear or failure.

The purpose of engine mounts is to:

1. Support the engine’s weight and maintain its position within the vehicle.

2. Absorb and dampen vibrations and shocks generated by the engine, reducing noise and improving ride comfort.

3. Isolate the engine’s movements from the rest of the vehicle, preventing excessive vibrations from affecting other components.The benefits of using high-quality engine mounts include:

1. Improved ride comfort: Properly functioning engine mounts help reduce vibrations and noise, leading to a smoother and more comfortable driving experience.

2. Enhanced vehicle performance: Engine mounts play a crucial role in maintaining the engine’s stability and alignment, ensuring optimal performance and efficiency.

3. Longevity: Using durable and compatible engine mounts can help extend the lifespan of the engine and other vehicle components by reducing wear and tear caused by excessive vibrations.

4. Safety: Engine mounts contribute to the overall safety and stability of the vehicle by securely holding the engine in place and preventing excessive movement that could lead to accidents or damage.Overall, investing in high-quality, compatible engine mounts for your vehicle can lead to improved ride comfort, enhanced performance, longevity, and safety. Regular inspection and maintenance of engine mounts are essential to ensure their proper functioning and prevent potential issues.

SpecificationsTypeENGINE MOUNTINGLocationEngine CompartmentPositionFrontNotesHydraulicTYPE:Hydraulic$80.50 -

Front Engine Mount for Toyota Rav4, Corolla, Auris-TM-ZZE150FR;12361-28230-(B00R984UPM)

Engine mounts are components that secure the engine to the vehicle’s chassis and absorb vibrations and shocks generated by the engine during operation. They play a crucial role in supporting the engine’s weight, reducing noise and vibrations, and isolating the engine’s movements from the rest of the vehicle.

The placement of engine mounts varies depending on the vehicle’s design, but they are typically located between the engine and the vehicle’s frame or subframe. Engine mounts are designed to withstand the engine’s weight and the forces generated during acceleration, braking, and cornering.

When it comes to compatibility, it is essential to ensure that the engine mounts are compatible with the specific make and model of the vehicle. Using compatible engine mounts designed for your vehicle ensures proper fitment and functionality, reducing the risk of premature wear or failure.

The purpose of engine mounts is to:

1. Support the engine’s weight and maintain its position within the vehicle.

2. Absorb and dampen vibrations and shocks generated by the engine, reducing noise and improving ride comfort.

3. Isolate the engine’s movements from the rest of the vehicle, preventing excessive vibrations from affecting other components.The benefits of using high-quality engine mounts include:

1. Improved ride comfort: Properly functioning engine mounts help reduce vibrations and noise, leading to a smoother and more comfortable driving experience.

2. Enhanced vehicle performance: Engine mounts play a crucial role in maintaining the engine’s stability and alignment, ensuring optimal performance and efficiency.

3. Longevity: Using durable and compatible engine mounts can help extend the lifespan of the engine and other vehicle components by reducing wear and tear caused by excessive vibrations.

4. Safety: Engine mounts contribute to the overall safety and stability of the vehicle by securely holding the engine in place and preventing excessive movement that could lead to accidents or damage.Overall, investing in high-quality, compatible engine mounts for your vehicle can lead to improved ride comfort, enhanced performance, longevity, and safety. Regular inspection and maintenance of engine mounts are essential to ensure their proper functioning and prevent potential issues.

-

SpecificationsTypeENGINE MOUNTINGLocationEngine CompartmentPositionFrontTYPE:Solid

$59.99 -

-

Front Inner CV-Joint for Mitsubishi RVR, Lancer, ASX-0411-CY34AT, 3817A136- (B00HAOT15Y)

CV-joints, also known as constant velocity joints, are essential components in a vehicle’s drivetrain system. They are responsible for transferring power from the transmission to the wheels while allowing for smooth and flexible rotation at various angles.

Compatibility: CV-joints are designed to fit specific vehicle makes and models. It is crucial to ensure compatibility with your vehicle before purchasing a CV-joint to ensure proper fitment and functionality.

Purpose: The primary purpose of CV-joints is to provide a flexible connection between the transmission and the wheels. They allow the wheels to maintain a constant velocity while accommodating the up-and-down motion of the suspension system. This flexibility is necessary for smooth and efficient power transfer, especially during turns and uneven road surfaces.

Benefits:

1. Flexibility and Range of Motion: CV-joints allow the wheels to turn at different angles while maintaining a constant velocity. This flexibility ensures smooth and efficient power transfer, resulting in improved handling and maneuverability.

2. Reduced Vibrations: CV-joints are designed to absorb and dampen vibrations generated by the drivetrain. By minimizing vibrations, they contribute to a smoother and more comfortable driving experience.

3. Enhanced Durability: High-quality CV-joints are built to withstand the demands of daily driving. They are designed to handle the stresses and forces exerted during acceleration, braking, and turning, ensuring long-lasting performance and reliability.

4. Improved Fuel Efficiency: By maintaining a constant velocity and minimizing power loss, CV-joints contribute to improved fuel efficiency. They help optimize the transfer of power from the engine to the wheels, resulting in better fuel consumption.

5. Reduced Maintenance: Properly functioning CV-joints require less maintenance compared to worn-out or damaged ones. Regular inspection and maintenance of CV-joints can help prevent costly repairs and ensure the longevity of the drivetrain system.

When considering purchasing CV-joints, it is essential to consult your vehicle’s manufacturer specifications and seek professional advice to ensure compatibility and proper installation. Additionally, selecting high-quality CV-joints from reputable sources will help ensure optimal performance and longevity.

SpecificationsTypeCV-JOINTLocationFront Axle TransmissionPositionInner Left/RightA (Teeth)33A.B.S. (Teeth)w/oB (Ø, mm)40C (Teeth)27L (mm)161$65.90 -

Front Left Engine Mount for LEXUS ES200, TOYOTA Camry, Highlander, Venza- TM-2AZFELH, 12372-0P010, 12372-28200- (B00DM9Z6UK)

Engine mounts are components that secure the engine to the vehicle’s chassis and absorb vibrations and shocks generated by the engine during operation. They play a crucial role in supporting the engine’s weight, reducing noise and vibrations, and isolating the engine’s movements from the rest of the vehicle.

The placement of engine mounts varies depending on the vehicle’s design, but they are typically located between the engine and the vehicle’s frame or subframe. Engine mounts are designed to withstand the engine’s weight and the forces generated during acceleration, braking, and cornering.

When it comes to compatibility, it is essential to ensure that the engine mounts are compatible with the specific make and model of the vehicle. Using compatible engine mounts designed for your vehicle ensures proper fitment and functionality, reducing the risk of premature wear or failure.

The purpose of engine mounts is to:

1. Support the engine’s weight and maintain its position within the vehicle.

2. Absorb and dampen vibrations and shocks generated by the engine, reducing noise and improving ride comfort.

3. Isolate the engine’s movements from the rest of the vehicle, preventing excessive vibrations from affecting other components.The benefits of using high-quality engine mounts include:

1. Improved ride comfort: Properly functioning engine mounts help reduce vibrations and noise, leading to a smoother and more comfortable driving experience.

2. Enhanced vehicle performance: Engine mounts play a crucial role in maintaining the engine’s stability and alignment, ensuring optimal performance and efficiency.

3. Longevity: Using durable and compatible engine mounts can help extend the lifespan of the engine and other vehicle components by reducing wear and tear caused by excessive vibrations.

4. Safety: Engine mounts contribute to the overall safety and stability of the vehicle by securely holding the engine in place and preventing excessive movement that could lead to accidents or damage.Overall, investing in high-quality, compatible engine mounts for your vehicle can lead to improved ride comfort, enhanced performance, longevity, and safety. Regular inspection and maintenance of engine mounts are essential to ensure their proper functioning and prevent potential issues.

SpecificationsTypeENGINE MOUNTINGLocationEngine CompartmentPositionFront LeftTYPE:Hydraulic$139.90